sheet metal drawing operation is used to make

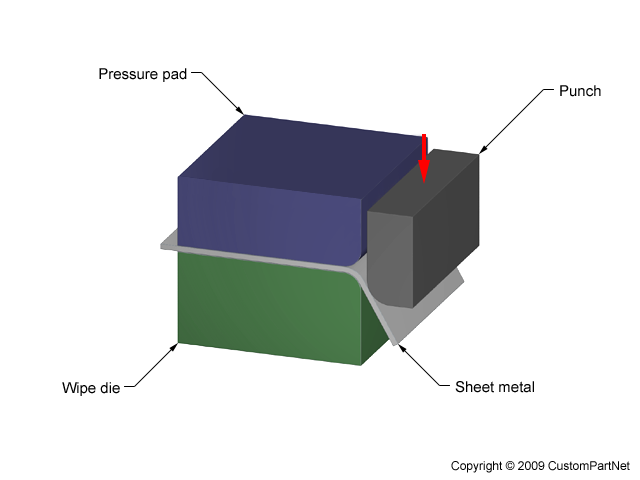

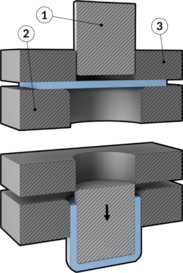

The punch-die clearance is slightly larger than the thickness of the sheet metal to be deep drawn. The punching operation removes the scrap material from the larger pieces of sheet metal stock by applying high shearing force.

Bending This step includes bending sheet metal for creating the metal components.

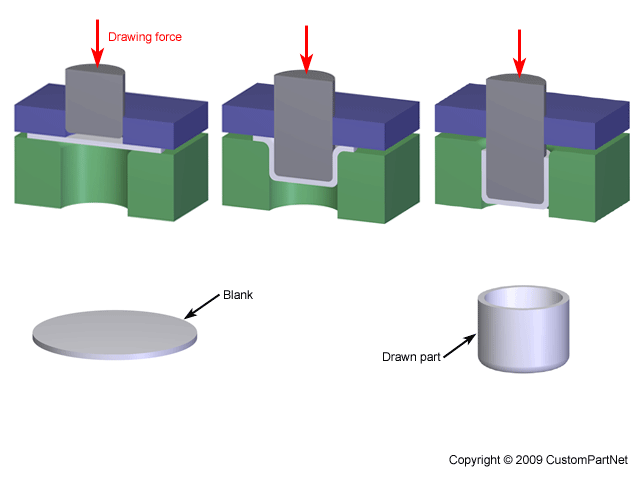

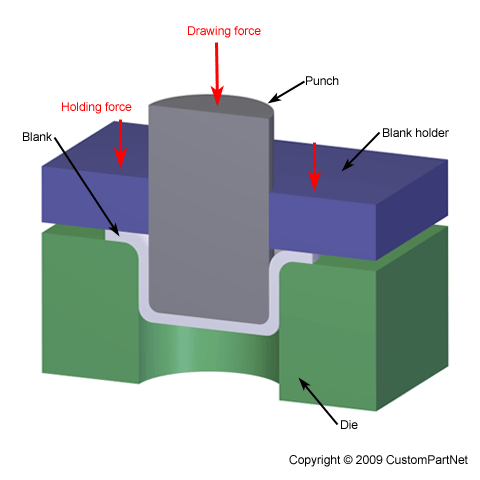

. Blank holder ring on cushion Compressible cushion Sheet metal stampingdrawing car industry 90million cars and commercial vehicles produced worldwide in 2014. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch. The punch press fdrives the punch downward at high speed through the sheet and into the die below.

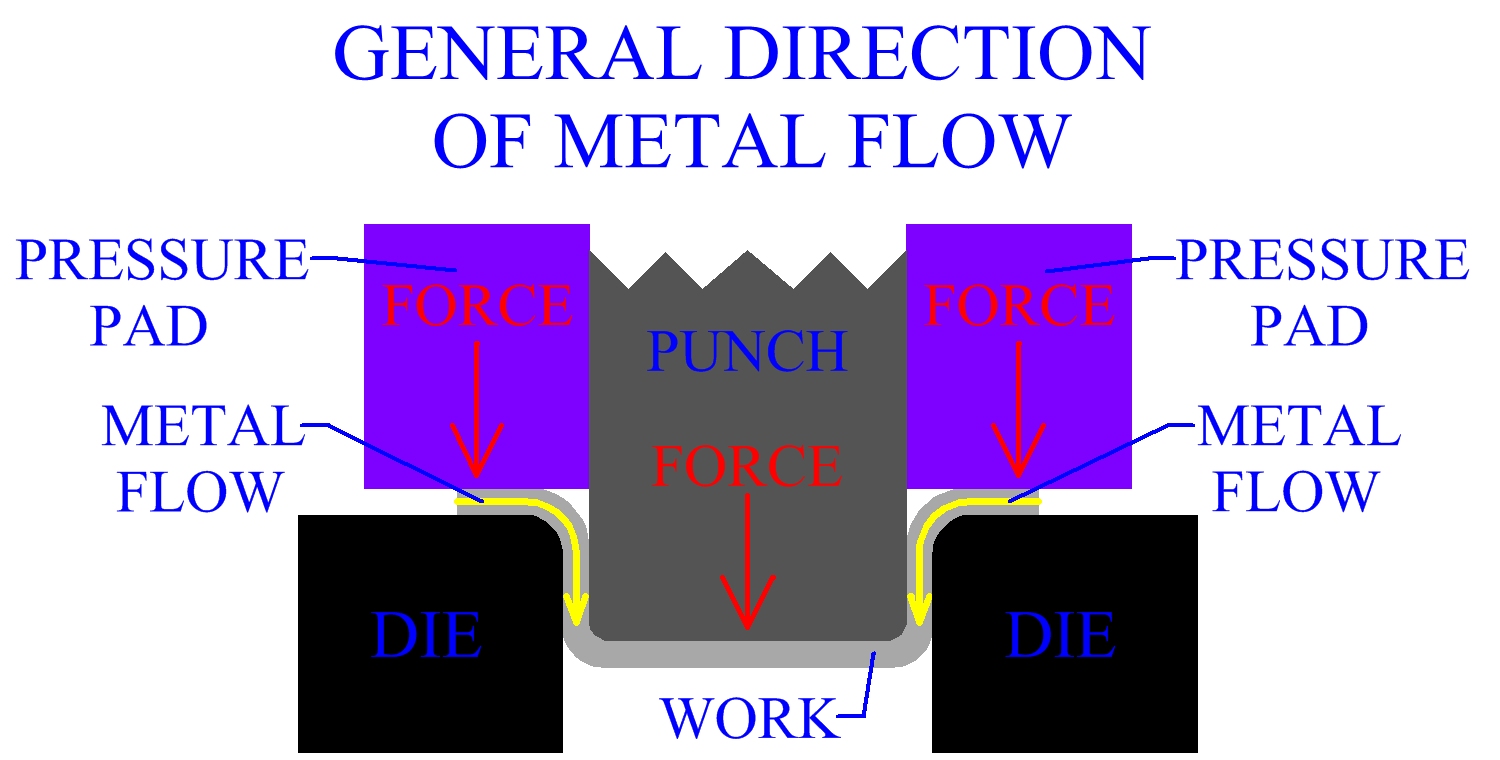

The pressure pad removes all the wrinkles meanwhile. Bends in the same plane should be designed in the same direction. Sheet is held by jaws or drawbeads at both the ends and then stretched by punch such.

Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch. True False Coining is a bulk deformation process also used in sheet-metal work in which fine details in a die are impressed into the. True False Coining is a bulk deformation process also used in sheet-metal work in which fine details in a die are impressed into the.

As the load applied through the punch the sheet metal is forced to. Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts. Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity.

Distance D 25T R see fig. Bends can give strength and shape to a part and are formed in a machine using bend brakes. Bending of Tube Stock.

Deep drawing of sheet metal is performed with a punch and die. Stamping Auto body panels 3 to 5 dies each. Cooper Sheet Metal Forming Ch.

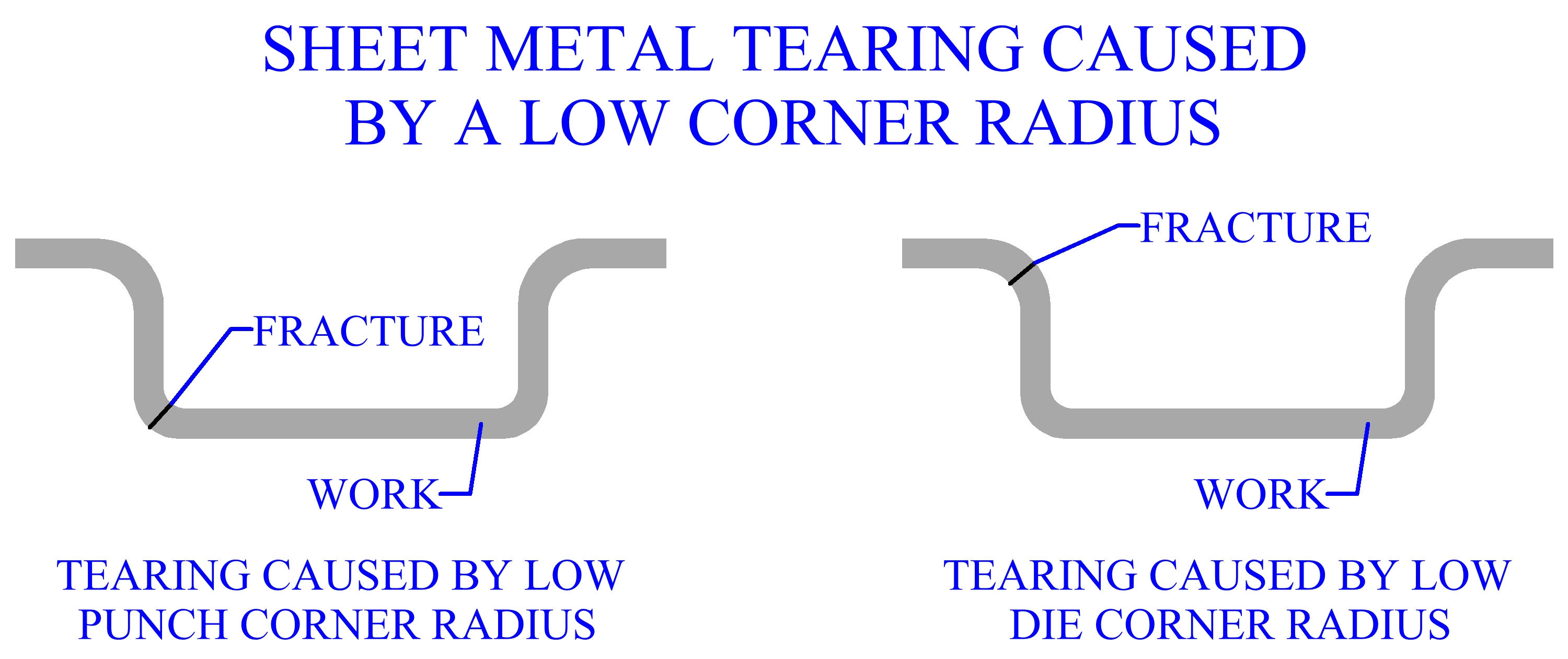

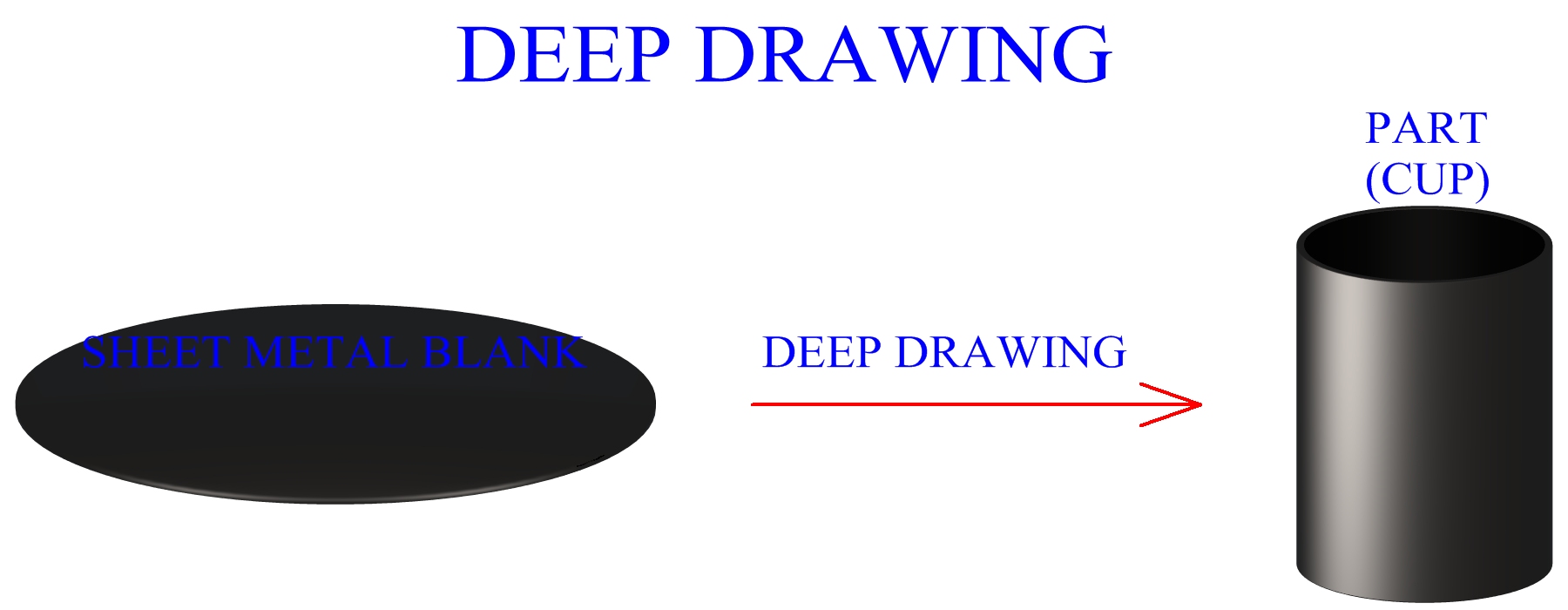

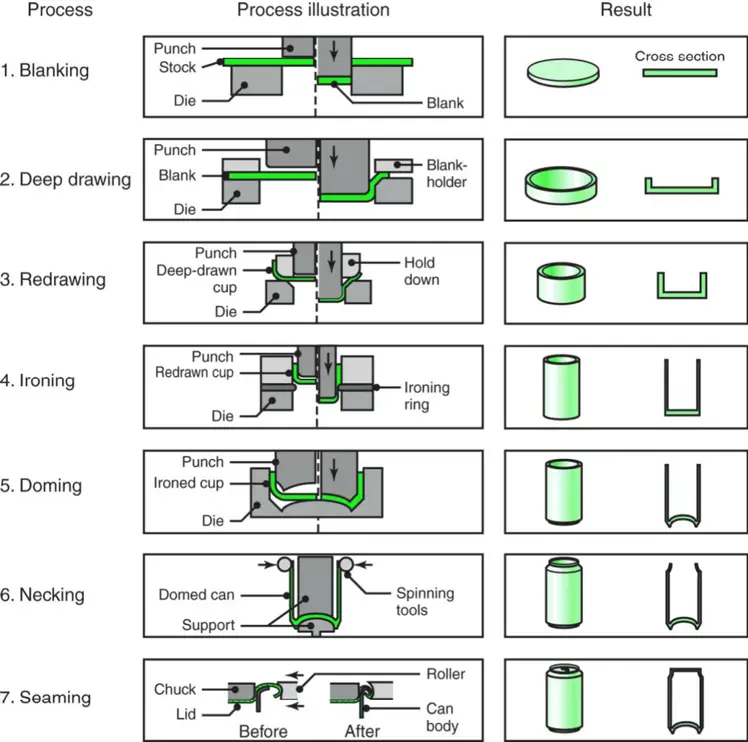

The deep-drawing process converts a sheet metal blank into a cylindrical component with one side open. There is a small clearance between the edge of the punch and the die causing the material to. The process involves a punch with a round comer and a die with a large radius.

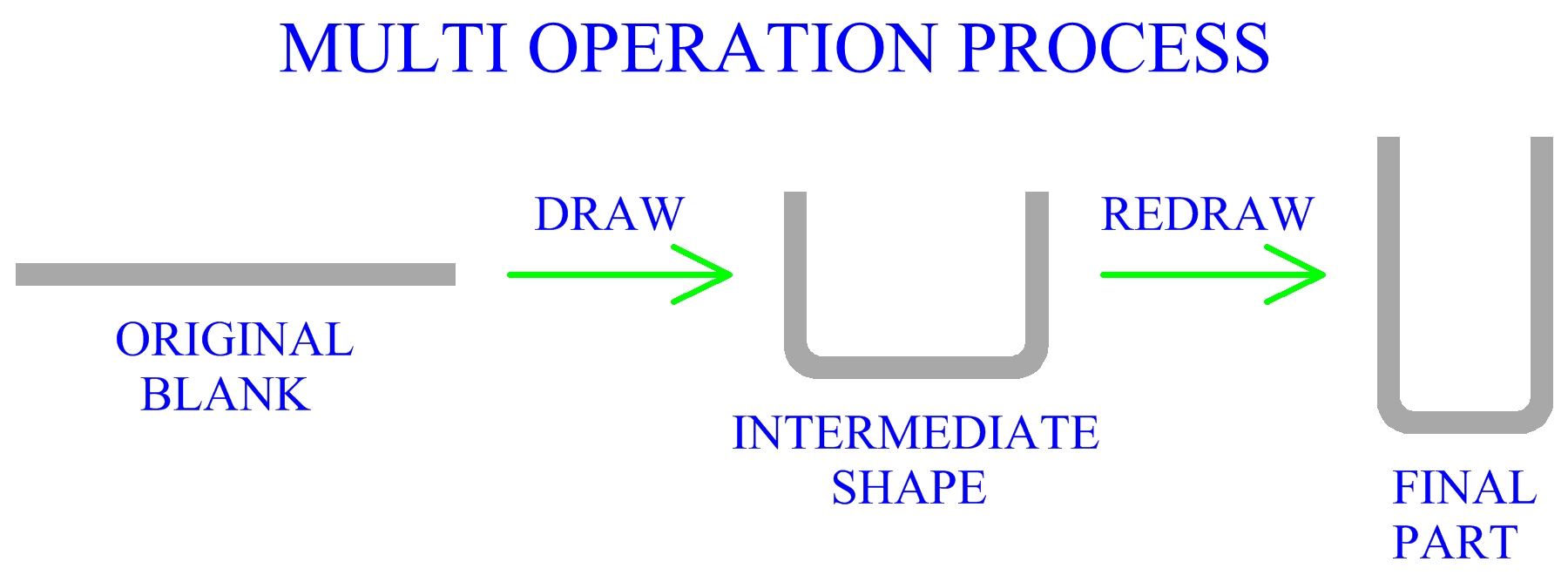

Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch. Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts. A lot of deeper products can be formed with repeated deep drawing.

Used for sheet metal working is a machine tool with a stationary bed and a powered ram or slide that can be driven toward and away from the bed to perform various cutting and forming operations. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch. Bending of Tube Stock.

Sheet Metal Forming 2810 D. Bending This step includes bending sheet metal for creating the metal components. In the operation the sheet metal is clamped.

Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts. Sheet metal operations are mostly termed cold metal operations without heat or fire like shearing and cutting with the use of guillotine and saw punching to form metal parts like spoons and forks in a press drilling holes by means of drill bits in a drill press grinding and sanding to smoothen or make rough surface preparation prior to additional operation bending to form cabinets and. The punch is the desired shape of the base of the part once drawn.

Sheet metal is used in various products like machinery building roofs car bodies airplanes and much more. C Form height to thickness ratio To determine the minimum form height for sheet metal use the following formula. It is an operation of.

D 25T R see below The height can be. The most common sheet metal form is a bend. Introduction Cutting and forming thin sheets of metal usually performed as cold working Sheet metal 04 164 to 6 mm 14in thick.

The die cavity matches the punch and is a little wider to allow for its passage as well as clearance. Usually the coils used range from 7 to 20 gauges. The punching process requires a punch press sheet metal stock punch and die.

Sheet metal drawing operation is used to make a wire. This setup is similar to sheet metal cutting operations. Where the die holder is.

Drawing Sheet metal forming operation used to make cup shaped box shaped or other complex curved hollow shaped parts Performed by placing a piece of sheet metal over a die cavity and then pushing the metal into the opening with a punch. Sheet Metal Cutting using Punching Operation. For cutting sheet meatal part a combination of punching operations in various sizes and shapes rectangular and circular are used.

Relative positions of the bed and ram. To save the cost of punching or drilling in a secondary operation the following formulas can be used to calculate the minimum distance required. Since sheet metal cannot be bent to a 90-degree position without breaking at sharp corners all bends will have an acceptable bend radius.

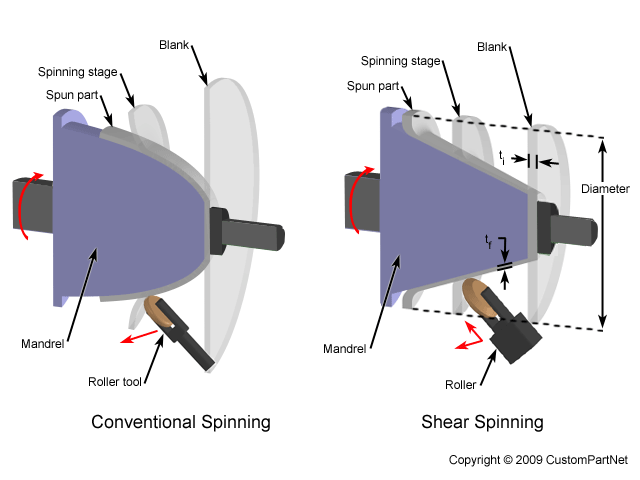

Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape change. The deep drawing process is used to manufacture sheet metal parts in large volumes for various industries. 16 Kalpakjian Design for Sheetmetal Working.

Beverage cans ammunition shells automobile body panels. In a blanking operation to produce steel washer the maximum punch load used in 2 x 10 5 NThe plate thickness is 4 mm and percentage penetration.

Sheet Metal Tools Cutting Marking Bending Tools

9 Different Types Of Sheet Metal Operations With Diagram Pdf

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing An Overview Sciencedirect Topics

Sheet Metal Forming An Overview Sciencedirect Topics

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing An Overview Sciencedirect Topics

Sheet Metal Forming Processes And Equipment Machinemfg